The production of the automotive industry is one of the main sectors of products exported in the United States according to the OECD.

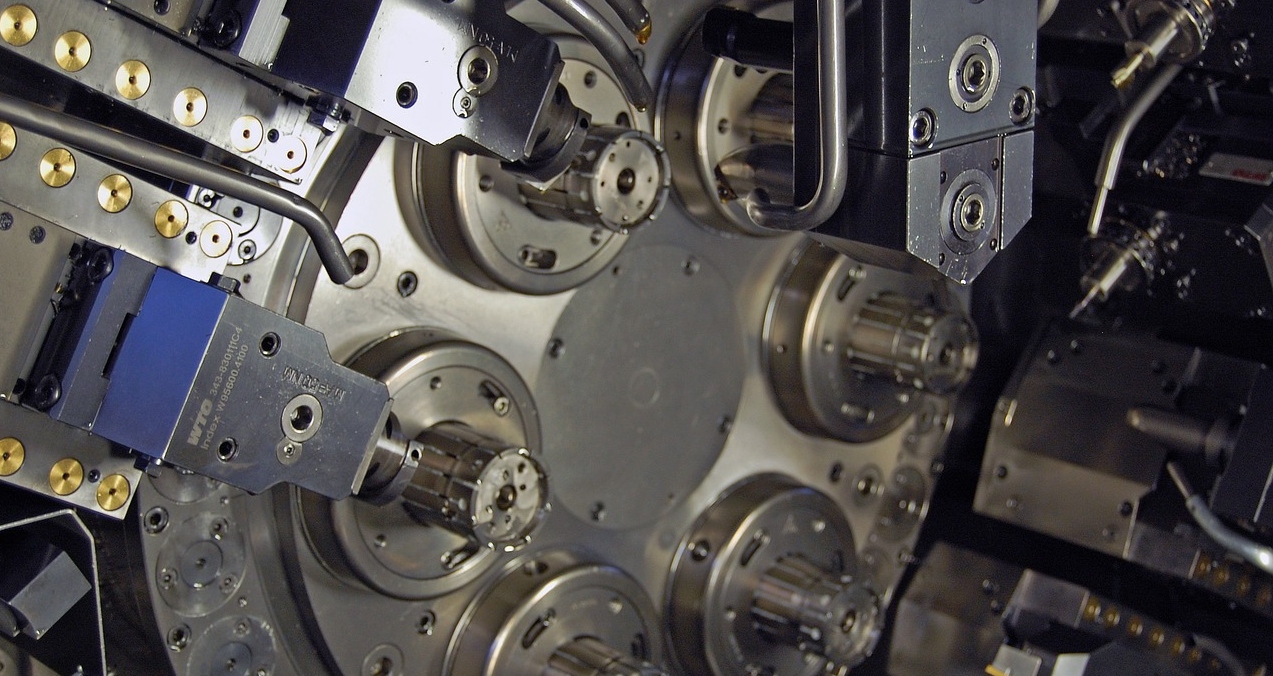

That is why it requires a production that is in time and form. Nowadays CNC machines achieve this, but for an increase in production as well as a reduction in costs, the ideal is to have a 5-axis CNC machine.

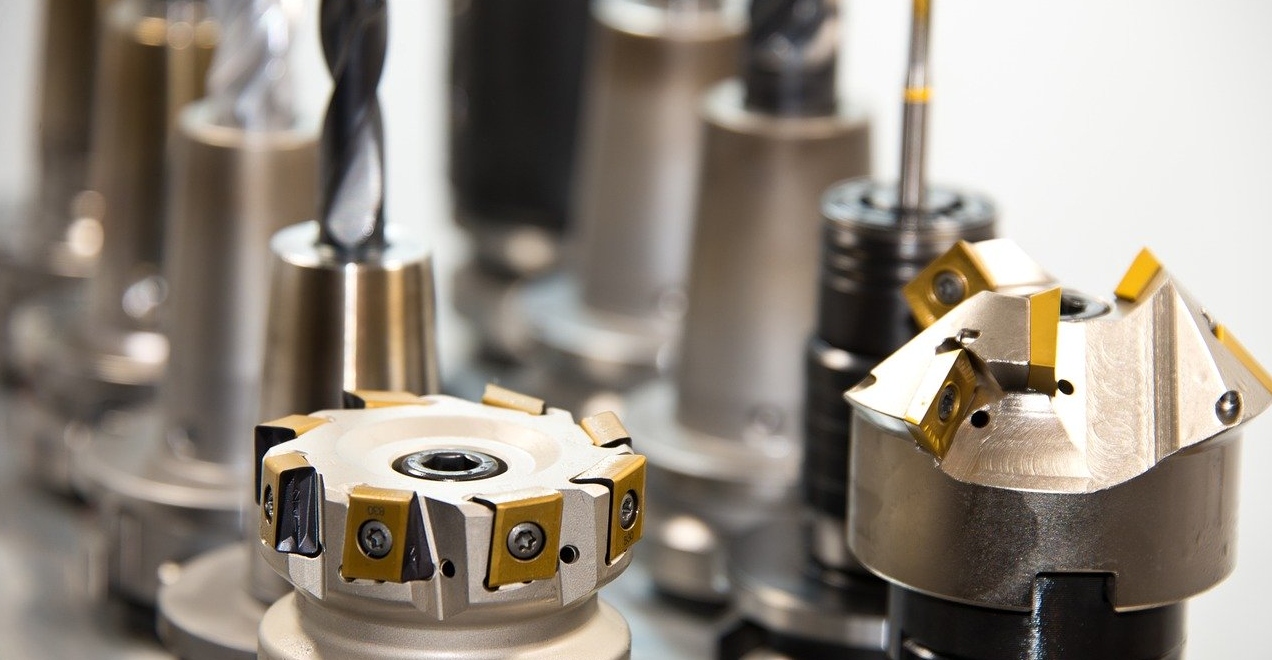

In general, the machines have 3 axes: radial, axial and tangential that offer drilling, milling or threading; although this helps the part not require more manual intervention, it is not sufficient for a certain type of finishing. Multi-axis machines offer greater possibilities for working, so no manual readjustments or set-ups are needed to work with another surface area.

In turn, it offers the possibility of creating pieces with more complex finishes and with different materials. This translates into space and machine savings by having a machining center that meets the same needs as 2 or 3 machines.